Analysis and Introduction of Grinding Machine Usage Skills for Diamond Grinding Wheel

Analysis and Introduction of the Techniques for Using Diamond Grinding Wheels in Grinding Machines

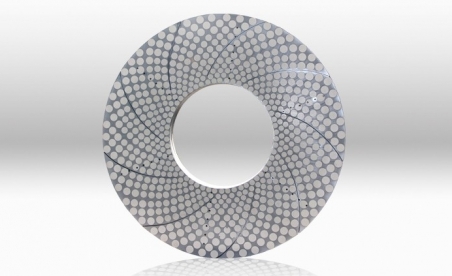

Ultra hard grinding wheel, especially high-speed grinding, requires good machining stability, low vibration, and high linear speed. Therefore, there are certain requirements for grinding machines:

(1) The rotation accuracy of the diamond grinding wheel spindle should be high.

(2) The rigidity of the grinding machine is better, and it is generally required to be about 50% higher than that of a regular grinding machine, usually not less than 100N/ μ The number of m is even greater.

(3) The accuracy of the feed system of the grinding machine should be high, and the feed speed should be uniform and correct. The longitudinal feed speed should be small, reaching 0.3m/min, and the transverse feed (cutting depth) should be 0.001~0.002mm per single stroke to ensure the dimensional accuracy, geometric shape accuracy, and surface roughness of the grinding.

(4) The moving parts of the grinding machine, such as the headstock spindle and bearing parts, and the feed motion guide rail part, should have reliable seals to prevent superhard abrasive from entering and accelerating the wear of the machine parts.

(5) There should be a relatively complete grinding fluid filtration and supply system, with a filtration accuracy of less than 0.5 μ M.

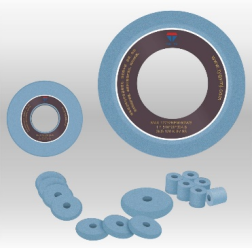

(6) Each part of the grinding machine should have corresponding vibration prevention and isolation measures, and the diamond grinding wheel should be finely balanced.