Convenience of surface sand treatment with steel shot

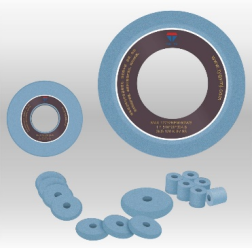

The steel shot is made of selected raw materials such as scrap steel, with the addition of rare metals and the optimal ratio of alloys. It is melted in an electric furnace and transformed into steel particles through modern equipment production. After multiple electric heating treatments and automatic screening, its chemical composition and particle size are strictly controlled during the process of forming steel particles from liquid metal to ensure that its mechanical properties meet various purposes. In every production process, there is the strictest quality management. The steel balls produced are tightly organized internally, not easily broken, with uniform particle size distribution, appropriate hardness, strong impact resistance, and long service life.

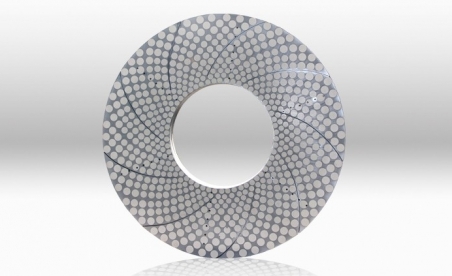

According to the work requirements of automobile manufacturers, the steel plates and some casting parts used need to be polished, but the strength and original appearance of the steel plates cannot be damaged. The appearance of the casting parts should ensure cleanliness and aesthetics. Due to the irregularity of automotive parts, different polishing machines are required to complete them. The shot blasting machines that need to be used include drum type, rotary table type, track type, and through type shot blasting cleaning machines, and different machines handle different workpieces.

Steel shot is widely used for descaling and rust removal of steel workpieces before coating, and centrifugal shot blasting equipment is often used in this situation. The shape of the ball and its smaller hardness prevent the steel shot from causing significant wear on the equipment. Steel shot is also widely used in the casting industry. After the workpiece is removed from the mold, the sand on the surface of the workpiece is removed with steel shot.

Melt high-quality molten steel, then spray it with a high-pressure water gun to form steel balls. The formed steel balls are reheated to homogenize and then quenched. The quenched steel shot is dried and reheated and tempered in the furnace to achieve appropriate hardness. The tempered steel shot is screened through a mechanical sieve and classified into grades that meet SEA standards for use in shot blasting equipment.